欢迎您注册蒲公英

您需要 登录 才可以下载或查看,没有帐号?立即注册

x

本帖最后由 验证资料收集 于 2020-7-10 12:50 编辑

​上一期我们分享了第一章节,今天继续第二章节部分内容。

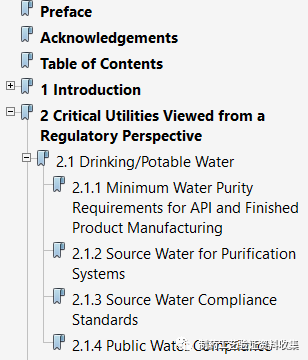

2 CriticalUtilitiesViewedfroma Regulatory Perspective从监管角度看关键公用系统 ACritical Utility (CU) is defined by ISPE [14] as: “Utility that has theidentified potential to impact product quality or performance in a significantway.”This GPG focuses on water systems (specifically PW, WFI, and Pure Steam); however it isrelevant to also address some of the systems/utilities that feed water systems,specifically potable water and pretreated water,as these grades of water are important to overall compliance. Process gases aretouched on in this Guide as well, albeit to a lesser extent as they typicallydo not present the same degree of difficultyin maintaining compliance.ISPE [14] 将关键公用系统(CU)定义为:“确定具有潜在重大影响产品质量或性能的公用系统。”该GPG专注于水系统(特别是PW,WFI和纯蒸汽);然而,它也涉及到供水系统的一些其他系统或公用工程方面,特别是饮用水和预处理水,因为这些等级的水对整体合规性很重要。本指南中也涉及了工艺气体,因为它们在维持合规性方面的困难通常是没达到同样程度,所以篇幅较小。 CUs are special in that they canbe considered a raw material, and therefore are subject to GxPrequirements. However, with the continuous generation anddistribution of water and steam, and the constant availability of compressedgases including air, it is notfeasible to take the traditional approach of identifying these materials by adiscrete lot number, testing the lot,and releasing for production. Continuously produced utilities are typicallyused before all results are available. CU的特殊之处在于它们可以被视为原料,因此必须遵守GxP相关的要求。但是,随着水和蒸汽的连续的制备和分配,以及包括空气在内的压缩气体的持续稳定性,采用传统的方法即通过不连续的批号来识别这些物料,测试该批并批准释放以进行生产是不可行的。连续制备的公用系统通常在检测结果可用之前已被使用。 Additionally, since these CU have a broad impact across multiple productsand processes at a manufacturing site, they are considered to entail asignificantly higher risk to product quality and subsequently, to patient safety.此外,由于这些CU对生产现场的多个产品或工艺具有广泛的影响,因此它们被认为对产品质量以及后期对患者安全的风险显著增加。 For these reasons, regulatoryscrutiny of CU systems often includes more elements of the quality system thataddress monitoring, control, maintenance, and calibration than is seen for anoncritical utility system. 基于这些原因,对关键公用系统的监管审查通常包括更多的质量体系要素,这些要素涉及监控、控制、维护和校准,而非关键的公用系统则不需要。 2.1 Drinking/PotableWater饮用水

Drinking water, also referred to as potable water, must comply with appropriate regulatoryrequirements (such as defined by US EPA[6], WHO [8], etc.) and is the minimumquality of water to be used in pharmaceutical manufacturing (i.e., variouspharmacopeias, and GMPs found in the FDA21CFR Parts 210 [15] and 211 [16], andelsewhere2). 直饮水,也称为饮用水,必须符合适当的监管要求(如美国环保署[6]、世界卫生组织[8]等的规定),并且是制药生产中使用的最低水质的水(即,FDA 21 CFR第210[15]和211[16]部分中的各种药典和GMP,以及其他地方标准2)。 Since this is the onlyspecifically mentioned water in the GMPregulations,it is clearly important to regulatory authorities that a lower quality of waternot be used in pharmaceutical manufacturing and that the users have taken stepsto ensure that a lower, potentiallyunsafe quality of water is not inadvertently utilized.This puts the burden of proof on the users of this water toensure the quality meets minimum requirements and is suitable for its intendeduse. 由于这是GMP法规中唯一明确提到的水,因此对于监管机构来说,不在药品生产中使用低质量的水,用户已采取措施确保不会无意中使用质量较低、可能不安全的水,这一点对监管部门来说是很重要的。这就要求用户承担举证责任,以确保水质符合最低要求并适合其预期用途。

2.1.1Minimum Water Purity Requirements for API and Finished Product Manufacturing原料药和制剂生产最低水纯度要求

According to ICH Q7 [5], theminimum water quality to be used forAPImanufacture and in the pharmaceutical facility in general, is water thatcomplies with WHO Guidelines for Drinking-WaterQuality3[8]. 根据ICH Q7[5],原料药生产和制药设施中使用的最低水质是符合世卫组织饮用水质量指南3[8]的水。 Depending on the nature of theAPI processing and its final microbial andchemical attributes, water of a purity level higher than potable quality may beneeded.This is particularlyimportant in the latter stages of synthesis or purification, where removal ofimpurities introduced with the water may not be accomplished by these finalAPI processing steps [5]. 根据原料药生产的性质及其最终微生物和化学特性,可能需要纯度高于饮用水质量的水。在合成或纯化的后期阶段,这一点尤为重要,因为这些最终原料加工步骤可能无法去除随水引入的杂质[5]。 Most pharmacopeias require theminimum water quality used forAPIand excipient manufacture to be potable or drinking water. USPGeneral NoticesSection 8.230.20 states4[12]: 大多数药典要求用于原料药和赋形剂生产的最低水质为直饮水或饮用水。USP一般通知第8.230.20节声明4[12]: “When used in the manufacture of officialsubstances, water shall meet the requirements for drinking wateras set forth in the U.S. Environmental ProtectionAgency National Primary Drinking Water Regulations (NPDWR) or in the drinking water regulationsof the European Union or of Japan, or in the World Health Organization’s Guidelines for Drinking Water Quality.Additionalspecifications may be required in monographs.” “当用于生产正规的药品时,水应符合美国环境保护局国家饮用水法规(NPDWR)或欧盟或日本饮用水法规中规定的饮用水要求,或者在世界卫生组织的饮用水质量指南中。专著中可能需要附加规范。” This means that if apharmaceutical manufacturer is in a jurisdiction other than the US, a memberstate of the EU, or Japan, the drinking water quality used in manufacturingmust comply with the one of these jurisdictions’drinking water regulations or WHO drinking water guidelines [8].Compliance with a differentjurisdiction’s drinking water regulations, if not oneof those four, is irrelevant to USPas well as FDA. 这意味着,如果药品生产企业位于美国、欧盟成员国或日本以外的司法管辖区,则生产过程中使用的饮用水质量必须符合其中一个司法管辖区的饮用水法规或世卫组织饮用水指南[8]。遵守不同司法管辖区的饮用水法规,如果不是这四项之一,与USP和FDA无关。 The Ph. Eur.[13] defines the minimum quality of water for use inAPI manufacture as: 欧洲药典[13] 将原料药生产中使用的最低水质定义为:

“complieswith the regulations on water intended for human consumption laid down by thecompetent authority.” “符合主管当局为人类用水制定的规定。”

Ph. Eur. does not explain who a competent authority is;however, it is understood to be the national entity in charge of the subject.It is the manufacturer’s responsibility to identify the applicable drinkingwater regulations of the country in which the product will be marketed andensure that the drinking water used in manufacturing meets those requirements. 欧洲药典没有解释谁是主管当局;但是,它被理解为负责这一问题的国家实体。生产企业有责任确定产品销售所在国适用的饮用水法规,并确保生产过程中使用的饮用水符合这些要求。 2 Note that at the time of this writing, the EMAdocument “Guideline on the quality ofwater for pharmaceutical use” [17] is pending implementation.请注意,在撰写本文时,EMA文件“药品用水质量指南”[17]正在等待实施。 3 Although the attributes specified in WHO Guidelines for Drinking-Water Quality are considered goals and notnecessarily mandatory for human consumption, compliance with all attributes ismandatory when used inAPImanufacture as well as for general pharmaceutical uses [5].虽然世卫组织饮用水质量指南中规定的属性被视为目标,并不一定是人类饮用的强制性属性,但在用于原料药生产以及用于一般制药用途[5]时,必须遵守所有属性。

2.1.2 SourceWaterforPurification Systems纯化系统水源

Another important use of drinkingwater is as source water for an on-site purification system that producescompendial grades of water, such asPW or WFI. When starting with one of the pharmacopeial drinking waters, allunsafe levels of impurities have theoretically been removed. So unless there isa possibility that these impurities could be reintroduced into thewater, there is no need to test fortheir absence in the further purified water.Instead, for finished water (i.e., PW or WFI), general non-specific tests forionic and organic impurities, that is, Conductivity and Total Organic Carbon (TOC),can be used to broadly define the finished water quality; however, several jurisdictions mandateadditional tests (seeAppendix 4). Itis noteworthy that the microbial content of the water undergoing purificationis also monitored, and, depending on the treatments selected, it may be thatthe levels of culturable bacteria in the non-compendial pretreatment waterincrease due to certain unit operations, and that this is acceptable. 饮用水的另一个重要用途是作为现场纯化系统的水源,该系统生产药典级的水,如PW或WFI。从药典中的一种饮用水开始,理论上所有不安全的杂质都被清除了。除非这些杂质有可能重新引入水中,否则无需在纯化水中进一步的检测。相反,对于成品水(即PW或WFI),离子和有机杂质(即电导率和总有机碳(TOC)的一般非特定测试可用于广泛定义成品水的质量;但是,一些管辖区要求进行额外的测试(见附录4)。值得注意的是,还对纯化水的微生物含量进行了监测,根据所选处理方法,非药典预处理水中可培养细菌的水平可能因某些单元操作而增加,这是可以接受的。

2.1.3 SourceWaterCompliance Standards水源符合标准

Similarly to the waterrequirements described forAPIs inUSPGeneral Notices, the USP[12] monographs for PW, WFI, and Pure Steam specify using one ofthe same four regional drinking water specification sets as the source water. 与《美国药典通则》中对原料药的用水要求类似,美国药典[12]专著中关于纯化水、注射用水和纯蒸汽的专著中规定使用四种区域饮用水规范中的一种作为源水。 In Europe [13] and Japan [18], aglobally accepted source water quality for purification into PW is WHO DrinkingWater [8]. However some pharmacopeiarequire that PW is used to supply the final purification step that generatesWFI. (SeeAppendix 4 for therequirements of the major pharmacopeias.) 在欧洲[13]和日本[18],世界公认的用于净化为PW的水源水质是世卫组织饮用水[8]。然而,一些药典要求使用纯化水来提供生产注射用水的最终纯化步骤。(主要药典要求见附录4)

2.1.4 PublicWaterCompliance公共用水合规性

When a public drinking watersource is used, the responsibility for complying with the drinking waterregulations of the region usually falls to the drinking water provider. However,it remains the user’s responsibility to ensure that complianceof all drinking water attributes has been achieved for water used at thepharmaceutical facility; this responsibility includes year-round verificationas there may be seasonal variability in water supply quality. 当使用公共饮用水源时,遵守该地区饮用水法规的责任通常由饮用水供应商承担。但是,用户仍有责任确保制药厂使用的水符合所有饮用水属性;这一责任包括全年核查,因为供水质量可能存在季节性变化。

谢谢关注,下期精彩继续!

备注:感谢ISPE的为大家提供了很多有用的书籍,版权归ISPE所用,如有侵权立即删除。

|  |手机版|蒲公英|ouryao|蒲公英

( 京ICP备14042168号-1 ) 增值电信业务经营许可证编号:京B2-20243455 互联网药品信息服务资格证书编号:(京)-非经营性-2024-0033

|手机版|蒲公英|ouryao|蒲公英

( 京ICP备14042168号-1 ) 增值电信业务经营许可证编号:京B2-20243455 互联网药品信息服务资格证书编号:(京)-非经营性-2024-0033